Simulating Hyperelastic Materials23 Iulie 2020

Ora: 09:00 (Romania)

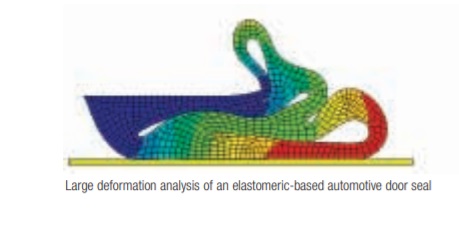

Hyperelastic rubber materials are used in many critical components, e.g., seals, gaskets and bushings across industries like oil and gas, automotive and aerospace. Simulating a hyperelastic material requires extra effort as they undergo a very large deformation, sometimes exceeding 800% of strain value. You can minimize these extra simulation efforts if you have the right simulation setup by choosing the right hyperelastic material model, contact settings, mesh and analysis settings at the beginning.

In this webinar, we will learn about the best practices in modeling hyperelastic materials using Ansys simulation solutions, including how to:

- Understand the basic physics of hyperleastic materials and why it is different than modeling metals.

- Curve-fit experimental test data and extract Ansys hyperelastic material model coefficients.

- Use modeling best practices, e.g., mesh, contact settings, analysis settings.

- Model fluid pressure penetration load.

- Debug a failed/unconverted solution.